您好,欢迎访问香港六码宝典资料大全官网!

业务咨询:138 2360 5006

UVC LED在流动水杀菌处理中的应用

分类:

新闻资讯

作者:

来源:

发布时间:

2020-07-15

【摘要】:

如何高效提升过流式水杀菌产品杀菌效率?UVC LED在流动水的应用

水在人体循环中占据重要地位,所以饮用水的净化和杀菌就显得格外重要。尤其在这场突发的公共卫生危机下,UVC LED净水领域赢得市场高度关注。

科技改变生活,随着水净化技术与设备不断革新与迭代,各类应用场景如医疗、教育等公众领域、家庭和办公等环境对有害微生物灭活需求大幅提升。人们对健康饮用水的意识也在不断加强,具备杀菌高效、使用便捷、无二次污染等优势的UVC LED过流式杀菌技术,则成为当下净水处理的首要解决方案。

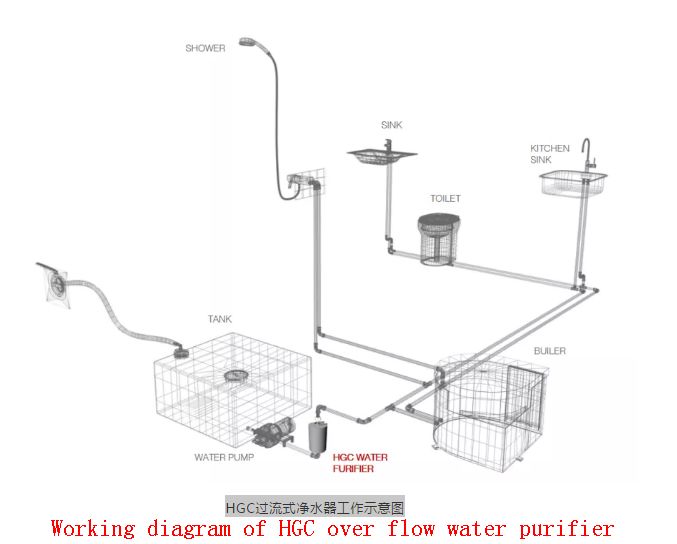

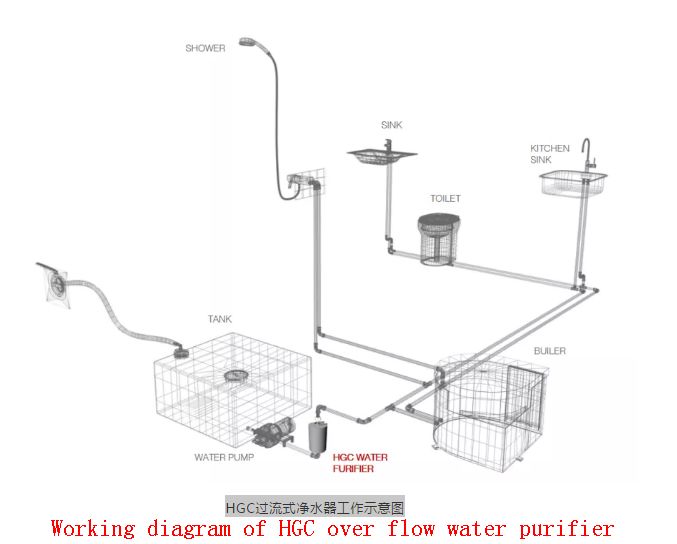

过流式水杀菌产品结构与应用场景

根据UVC LED相关器件应用要求,将UVC LED过流式水杀菌产品分为5个组成单元:入水口,出水口,杀菌腔体,UVC LED模组和产品主体结构。其中杀菌腔体和UVC LED模组内置于产品主体结构内,产品采用外部供电系统,并设计入水口及出水口供串联置入水流管路。

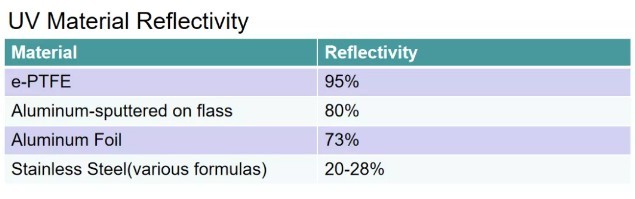

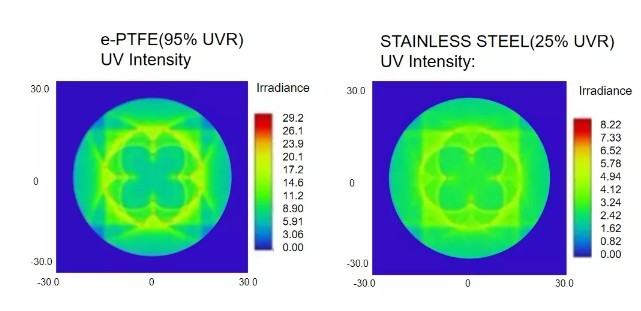

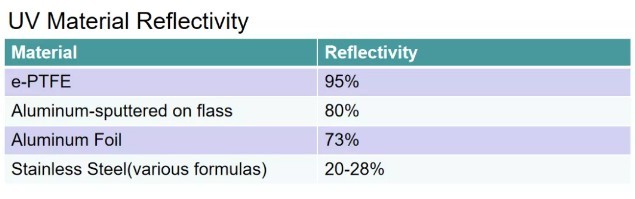

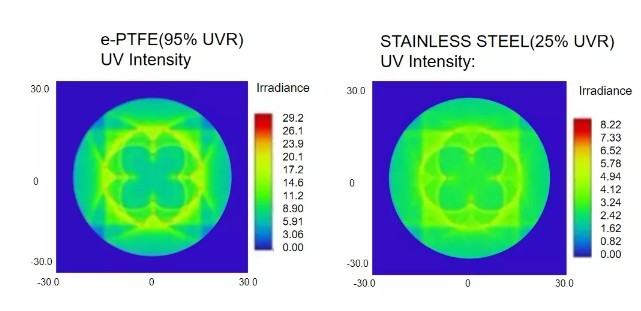

杀菌腔体光路设计及选材

1878年人类就发现了太阳光中的紫外线具有杀菌消毒作用,1906年人类发现了传递紫外光性能较好的石英材质灯管。采用石英材质是因为UVC穿透能力较弱,生活中常见的透明玻璃,透明塑料UVC都无法穿透。在过流式水杀菌的腔体中,透光材料通常选择石英材质,如石英透镜,石英管等。反光材料一般选择PTFE(聚四氟乙烯Poly tetra fluoroethylene)或铝材。

水与人类的健康密不可分,接触生活用水的产品选材需要采用食品级材料,国家对此有专门的食品接触性材料认证标准。因此在UVC LED过流式水杀菌产品选材中,不单要考虑材料对UVC杀菌效率的科学匹配,还要考虑到材料本身的安全性。HGC自主研发设计的过流式水杀菌产品,采用特殊反光材料,纯石英做透镜和透明管路,食品级硅胶做防水圈,产品涉水材料通过食品级认证,获得RoSH认证。

选择合适的材料后,制成特定结构的杀菌腔体时还要考虑光路设计,利用石英,空气,水的折射率差异,使UVC在腔体管路中传播射线与管壁的夹角尽量大于UVC在水与PTFE界面的全反射角度θ,使水路中UVC强度达到较高的数值,充分利用UVC光源。

过流式水杀菌整体杀菌效率提升——UVC灯珠热管理

过流式杀菌不仅注重光路设计与材料选择,这些技术细节也能影响产品的最终杀菌效率:

首先是UVC灯珠的热管理,由于UVC过流式水杀菌要求一次性杀菌率,所以UVC模组的设计光功率较高,UVC灯珠往往是高密度集中贴片,在工作时,UVC灯珠发出的大量热需要合理处理,否则会迅速光衰,导致杀菌率下降, HGC过流水杀菌系列采用水冷散热系统,产品使用过程中,UVC模组和流动的水不断循环换热,保证UVC LED的结温Tj处于合理工作温度。

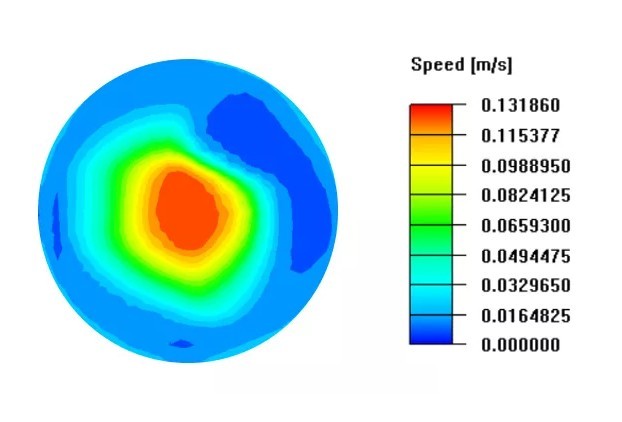

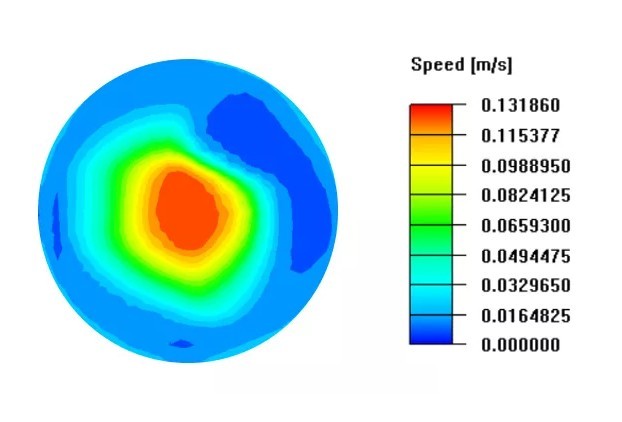

其次是管路中水流的设计,过流水杀菌产品的本质是水流从产品中流过而经过UVC的照射处理,故其流体需要做科学设计,原则上需要杀菌管路中水流处于层流模型,而避免紊流的出现,根据水流密度设计光照强度分布,才能保证最高的杀菌效率。

还有一些可以影响杀菌效率的因素,如UVC灯珠工作后易导致空气加热,热空气接触石英透镜结露,露水影响UVC光线在石英透镜的透过率,以及产品设计时的一些结构死角,易积垢和形成涡流等,这些对杀菌率不利的因素在产品设计中也要考虑。

过流式水杀菌产品是UVCLED的一项多专业融会贯通的典型终端应用,其产品设计需要的技术包括光学设计,热学设计,材料匹配,零件装配等诸多技术,HGC自主研发的过流式杀菌消毒净水终端产品系列,可以实现2-20L/min流速,99.99%的一次杀菌率,处于行业领先水平。

目前全球仍处于积极防疫期,我们将持续深耕UVC-LED应用领域,推出更高性价比、更高光效,更高可靠性的UVC器件与解决方案,为UVC产业高质量发展贡献积极的力量。

How to effectively improve the sterilization efficiency of over flow water sterilization products? Application of UVC led in flowing water

Water plays an important role in human circulation, so the purification and sterilization of drinking water is particularly important. Especially in this sudden public health crisis, UVC LED water purification field has won high market attention.

Technology changes life. With the continuous innovation and iteration of water purification technology and equipment, various application scenarios, such as medical treatment, education and other public areas, home and office environment, have greatly increased the demand for harmful microorganism inactivation. People's awareness of healthy drinking water is also constantly strengthened. UVC led over-flow sterilization technology, which has the advantages of high sterilization efficiency, convenient use and no secondary pollution, has become the primary solution for the current water treatment.

Structure and application scenarios of over flow water sterilization products

According to the application requirements of UVC LED related devices, UVC led over-flow water sterilization products are divided into five components: water inlet, water outlet, sterilization chamber, UVC LED module and main structure of the product. The sterilization chamber and UVC LED module are built into the main structure of the product, and the external power supply system is adopted for the product, and the water inlet and outlet are designed to connect in series into the water flow pipeline.

Light path design and material selection of sterilization chamber

In 1878, human beings discovered that ultraviolet rays in the sunlight have the function of sterilization and disinfection. In 1906, people discovered quartz lamps with better performance of transmitting ultraviolet light. Quartz material is used because of the weak penetration of UVC. The transparent glass and transparent plastic UVC can not penetrate. In the cavity of over-flow water sterilization, quartz material is usually selected as light transmitting material, such as quartz lens, quartz tube, etc. PTFE (polytetrafluoroethylene) or aluminum materials are generally selected as reflective materials.

Water is closely related to human health. Food grade materials should be used in the selection of products contacting with domestic water. The state has a special certification standard for food contact materials. Therefore, in the selection of UVC LED water sterilization products, not only the scientific matching of materials to UVC sterilization efficiency, but also the safety of materials should be considered. Our self-developed and designed over-flow water sterilization products use special reflective materials, pure quartz as lens and transparent pipeline, food grade silica gel as waterproof ring. The water-related materials of the products have passed food grade certification and obtained Rosh certification.

After selecting suitable materials, the design of light path should be considered when making sterilization cavity with specific structure. The angle between UVC propagating ray and pipe wall in the cavity pipeline should be greater than the total reflection angle θ of UVC at the interface between water and PTFE by making use of the refractive index difference of quartz, air and water, so that the UVC intensity in the water path can reach a higher value and make full use of UVC light source.

Improvement of overall sterilization efficiency of over flow water sterilization -- thermal management of UVC lamp beads

Over flow sterilization not only focuses on light path design and material selection, but also affects the final sterilization efficiency of the product

The first is the thermal management of UVC lamp beads. Since UVC over-flow water sterilization requires a one-time sterilization rate, the design light power of UVC module is high. The UVC lamp beads are usually high-density centralized patches. When working, a large amount of heat emitted by UVC lamp beads needs reasonable treatment, otherwise the light will quickly fade, leading to the decline of sterilization rate, HGC over water sterilization series adopts water cooling cooling system. During the use of the product, UVC module and flowing water continuously circulate and exchange heat to ensure that the junction temperature TJ of UVC LED is at a reasonable working temperature.

The second is the design of water flow in the pipeline. The essence of the product is that the water flows through the product and is irradiated by UVC. Therefore, the fluid needs to be scientifically designed. In principle, the water flow in the sterilization pipeline should be in the laminar flow model to avoid turbulence. The light intensity distribution should be designed according to the water flow density to ensure the highest sterilization efficiency.

There are also some factors that can affect the sterilization efficiency, such as air heating after UVC lamp beads work, condensation of hot air contact quartz lens, dew influence of dew on UVC light transmission rate in quartz lens, and some structural dead corners in product design, which are easy to scale and form eddy current, etc. These factors that are unfavorable to sterilization rate should also be considered in product design.

The over flow water sterilization product is a typical terminal application of UVLED with multi-disciplinary integration. The technology required for product design includes optical design, thermal design, material matching, parts assembly and many other technologies. The self-developed over-flow water sterilization and water purification terminal product series developed by HGC can achieve a flow rate of 2-20l / min and a sterilization rate of 99.99%, which is in the leading level of the industry。

At present, the world is still in the period of active epidemic prevention. We will continue to deepen the application of uvc-led, and introduce UVC devices and solutions with higher cost performance, higher light efficiency and higher reliability, so as to contribute to the high-quality development of UVC industry.

相关新闻